Need some assistance?

- Overview

-

By Type

Custom - Standard (AS568)

-

By Brand

Parker - Freudenberg

-

By Material

Nitrile - FKM

- EPDM

- FFKM

- Silicone

- Fluorosilicone

- PTFE

- Polyurethane

- FEP/PFA Encapsulated

- HNBR

- Overview

-

By Type

U-Cups - Wipers

- Wear Rings

- Overview

-

By Brand

Simmerring®

Need some assistance?

Need some assistance?

-

O-RINGS

- Overview

-

By Type

Custom - Standard (AS568)

-

By Brand

Parker - Freudenberg

-

By Material

Nitrile - FKM

- EPDM

- FFKM

- Silicone

- Fluorosilicone

- PTFE

- Polyurethane

- FEP/PFA Encapsulated

- HNBR

-

HYDRAULICS & PNEUMATICS

- Overview

-

By Type

U-Cups - Wipers

- Wear Rings

-

ROTARY SEALS

- Overview

-

By Brand

Simmerring®

- CUSTOM MOLDED

- GASKETS

- MACHINED RUBBER & PLASTICS

- EXTRUDED SHAPES & PROFILES

- SPECIALTY PRODUCTS

U-Cup Seals

Hydraulics & Pneumatics

U-cups, also known as symmetrical seals, U-rings, or U-seals because of their “U” shaped profile, are multipurpose sealing solutions suitable for hydraulic and pneumatic rods and pistons.

U-cups are crafted using diverse plastic or rubber materials that match the requirements of your specific application, ensuring a superior seal between different components.

Here at Wyatt Seal, we provide a wide range of high-quality U-cups that will work exceptionally well in various applications.

What Is a U-Cup Seal?

A U-cup is a specialized seal that is precisely fitted over two interlocking components, which may have varying material compositions. The primary function of a U-cup seal is to establish an airtight barrier that prevents any fluid from escaping. They are also resistant to high-pressure applications, maintaining their shape without warping or breaking. When pressure increases from the application, the U-cup's sealing lips become energized to form a tighter grip on the mated materials.

U-cups are used for both static (no movement) and dynamic (movement) parts, as they come in two designs: unloaded U-cup seals and loaded U-cup seals. They also come in varying lip profiles: standard U-cup, deep U-cup, or beveled (B-type) U-cup.

Loaded U-Cup Seals

Loaded U-cups have an O-ring or a quad ring, referred to as an expander, that is fitted between the two sealing lips. With the O-ring or quad ring, the sealing force of the loaded U-cup increases when used for low pressure applications. When the pressure rises, the loaded U-cup automatically compensates by increasing its sealing force.

Unloaded U-Cup Seals

As the name implies, unloaded U-cups do not come with an O-ring or quad ring between the lip seals. As such, if you have machinery that starts at low pressures that will increase during use, the unloaded U-cup will not automatically have its sealing force increase.

Standard U-Cup Seals

Standard U-cups have a square cross-section and can be used as a replacement for O-rings and hydraulic packing for rod and piston applications.

Deep U-Cup Seals

Deep U-cups are modified versions of the standard U-cups. They possess a rectangular cross-section with an increased axial depth. This deeper design provides greater levels of stability. Deep U-cups seals are often used to replace braid rope, and V or W packing.

Beveled (B) U-Cup Seals

Beveled U-cups are similar to the deep U-cup design with a deep cross-section. The major difference is the bevel on the back sealing lip. This beveled lip design provides an increase in squeezing power along the mated surfaces. Beveled U-cups also come as square B, which has a standard cross-section diameter.

U-Cup Seal Materials and Sizing

Here at Wyatt Seal, we offer U-cup seals that come in various materials to accommodate the type of application and working environment. Each material offers unique benefits:

- Polyurethane: Polyurethane U-cups have high abrasion resistance. They can handle friction with lower wear and tear.

- Rubber: Rubber U-cup seals are suitable for stretch fittings. The rubber material can ward off corrosion from the environment.

- Fabric: These U-cups come with fabric reinforcement that can be used in arduous environments.

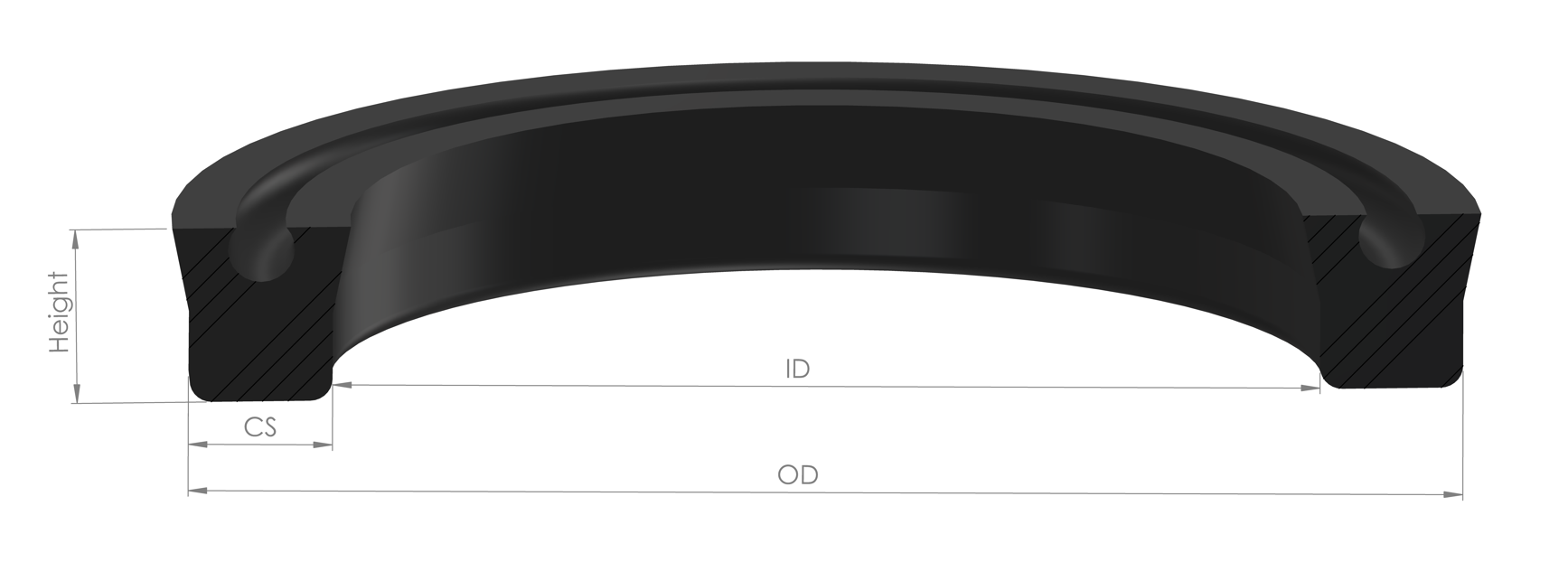

When sizing U-cup seals, there are various measurements to consider such as the inside diameter (ID), the outside diameter (OD), and the cross-section (CS).

The ID measurement is determined by measuring the inside of the U-shaped lips from the inside walls. The OD measurement is used for the outside walls of the lips or beveled lips.

The CS measurement is found by measuring the entire side of the U-cup seals cross-section.

Benefits of U-Cup Seals

U-cup seals offer several advantages for applications that require flexible and strong seals. They can be used interchangeably with other seal types for most piston and rod machinery. Depending on the material(s) used in the U-cup, they can withstand friction, corrosion, and rust while handling both low and high-pressure applications.

U-cup seals also utilize materials that can withstand a wide range of temperatures. This enables them to accommodate thermal expansion that can arise in mated materials as a result of fluctuations in fluid temperatures.

Common Uses and Applications

Most U-cups are used for hydraulic and pneumatic systems. They are also used on single-action pistons, for rod sealing of hydraulic cylinders, and ram sealing on hydraulic presses.

You may find U-cup seals in:

Finding the Right U-Cup for the Right Application

When it comes to U-cup seals, there are many factors to consider when searching for the right solution. You need to consider the fluid media, maximum pressure, service temperature, gland size, and other factors. Here at Wyatt Seal, our team of experts assists customers in finding the U-cup solution that will work best with their applications. Are you looking for the right U-cup seal for your equipment? Let's talk today.