Choosing the right sealing material is critical to performance, uptime, and overall equipment life—especially in hydraulic systems exposed to high pressure, temperature extremes, and constant motion.

Wyatt Seal Blog

When reliable sealing is critical, selecting the right elastomer makes all the difference. Two of the most capable materials on the market—FKM (fluoroelastomer) and FFKM (perfluoroelastomer)—are often compared for their impressive chemical and temperature resistance.reliability.

When a satellite is launched into orbit, there’s no room for error. Once it leaves Earth’s atmosphere, even a microscopic leak in a propulsion valve or sensor housing could mean millions of dollars in lost equipment—or lost data.

Choosing the right O-ring material is critical to the performance and longevity of your seal. Among the many options available, Viton® and nitrile stand out as two of the most widely used. Both offer strong sealing capabilities, reliable compression set, and distinct chemical resistance profiles. But how do you know which is the better fit for your application?

Seals serve as essential components across various industries, ensuring containment, preventing leaks, and maintaining operational efficiency. However, their effectiveness can be compromised by a range of defects, each with its own set of consequences.

In response to the imperative to reduce greenhouse gas emissions, Carbon Capture Utilization and Storage (CCUS) has emerged as a vital solution. CCUS technologies offer the potential to capture and store carbon dioxide (CO2) emissions from industrial sources, preventing their release into the atmosphere.

Learn how to select the perfect seal based on pressure dynamics related to the environment, material properties, and testing best practices to ensure optimal performance.

This guide simplifies seal selection by focusing on chemical compatibility. It considers media types, environmental factors, application types, temperature, and pressure impact. It's a helpful resource to ensure you find the right seal for any application.

Understand the importance of temperature ranges, media, application type, and pressure in seal performance and durability to choose the right O-ring. This guide will help you select the ideal material for your specific needs, ensuring optimal functionality.

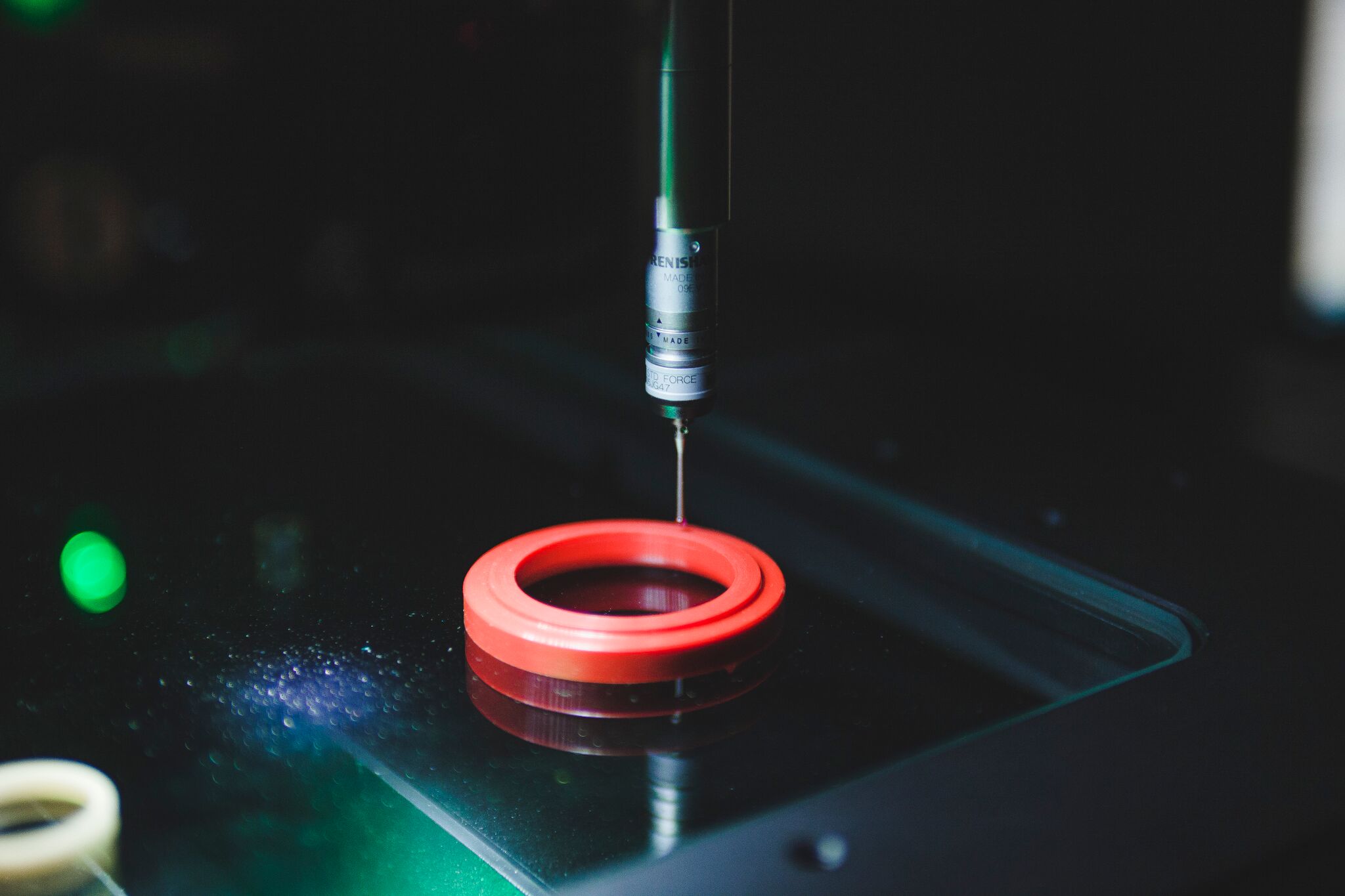

Designing the right seal for a challenging application can feel overwhelming—especially when failure isn’t an option. That’s where Finite Element Analysis (FEA) comes in.

Not all O-rings are created equal when it comes to O-ring shelf life, as materials deteriorate at different rates. O-rings play an essential role in many types of equipment, and they may fail if the seals are not stored properly or past their useful lifespan.

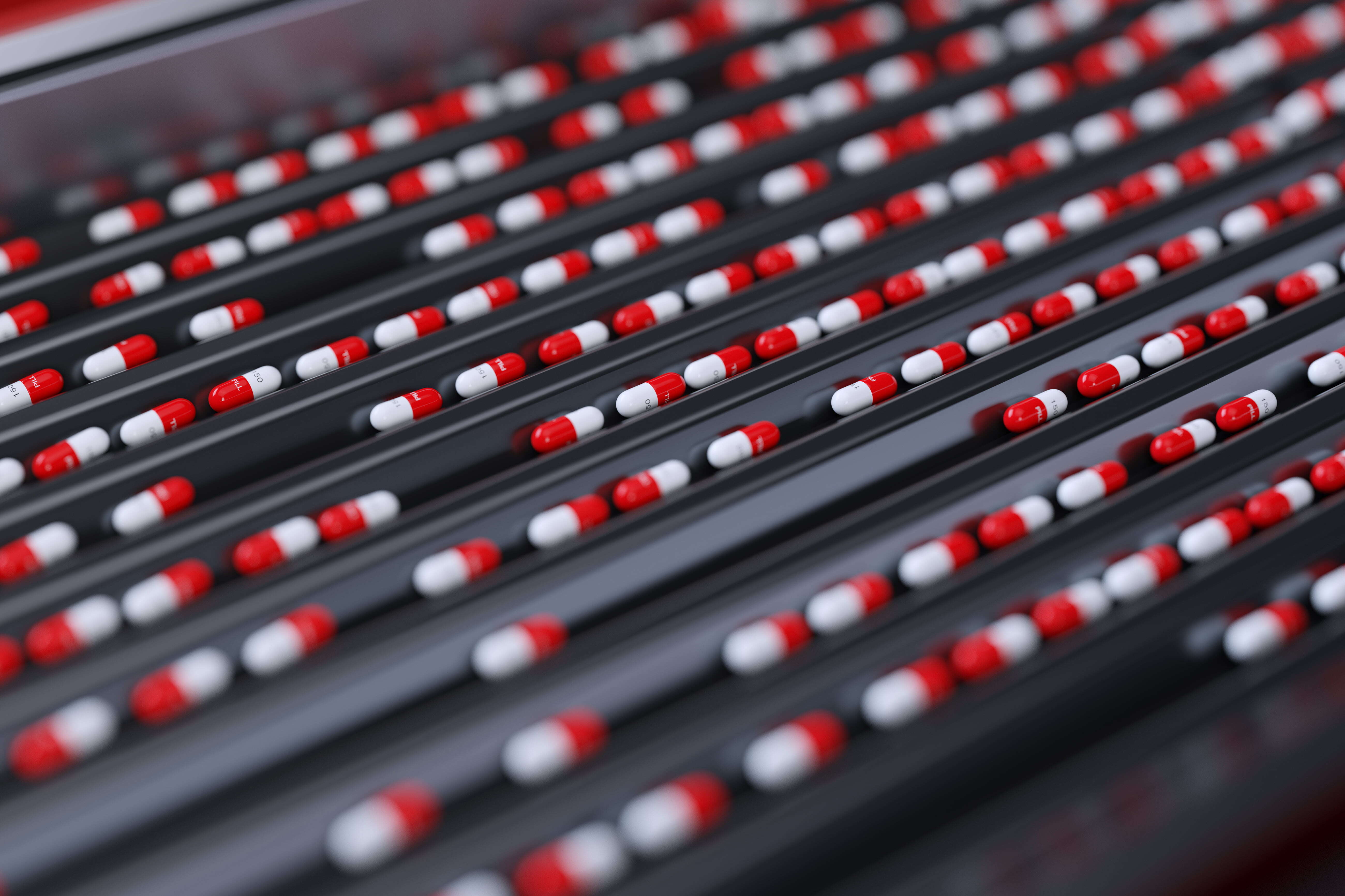

In pharmaceutical manufacturing, maintaining product integrity, preventing contamination, and ensuring compliance with regulations are top priorities.

Here's a detailed guide on how temperature range, pressure, and fluids and viscosity specifications will dictate the type of industrial seal you need.

Metal detectable O-rings are essential for maintaining safety in the food and beverage industry’s production processes. Combining rubber and metal fillers, these innovative seals ensure that any contamination caused by seal degradation is quickly identified using metal detectors or X-ray scanners.

When it comes to sealing solutions, choosing the right O-ring is critical, and one of the most important factors to consider is shore hardness. But what exactly does this term mean for your project?

At Wyatt Seal, we are proud to offer a range of high-quality Parker Hannifin metal seals designed to meet the most demanding sealing requirements. These seals are engineered to perform under extreme conditions, providing reliable solutions for applications where traditional elastomeric seals might not suffice.

Deciding between a standard seal and a custom seal involves several considerations that relate directly to your specific needs and the demands of your application.

When designing fluid containment systems, the comprehension of both face seals and radial seals holds significant importance.

When an O-ring is said to be “food grade,” it’s understood to meet a rigorous standard of quality and cleanliness.

Food and beverage manufacturers operate in some of the most highly regulated production environments in the world. From sanitation chemicals and temperature swings to strict FDA requirements, sealing components must perform flawlessly to protect product quality and keep lines running.

Central to the effectiveness of O-rings is the concept of "squeeze" – a measurement of the deformation they undergo when compressed against their mating hardware.