Introduction

We know that selecting the right seal for your application can be time-intensive. And with countless options and variables to consider, it's easy to feel overwhelmed.

We get it, and we're here to help.

This guide is designed to simplify the process and help you understand the ins and outs of chemical compatibility so you can choose the right seal for your needs as quickly and efficiently as possible.

The Role of Chemical Compatibility in Seal Selection

Chemical compatibility is a crucial element of your seal's performance. A mismatch can lead to premature seal degradation, operational setbacks, and unexpected costs. But, the correct pairing can lead to lasting, high-performing results. That's why it's so important to understand how the material interacts with the media it will be exposed to when selecting a seal based on chemical compatibility.

Using Media to Determine a Seal’s Chemical Compatibility

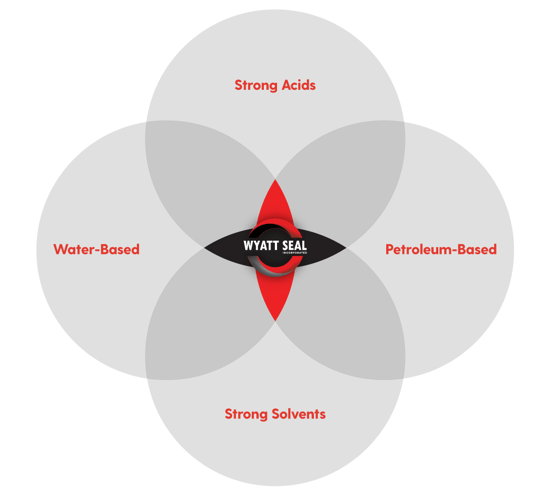

When you're dealing with a lot of chemicals, it can get overwhelming. One way to simplify your search process is to consider the media first. Imagine a Venn diagram with four overlapping circles: water-based, petroleum-based, strong acids/bases, and strong solvents. These four distinct media groups take you down a different path in your search. So, you can look at where the circles overlap for broad compatibility or use these groupings to narrow your choices and focus your search.

Other Key Factors Influencing a Seal’s Chemical Compatibility

-

Environmental: Depending on the environment, such as in Life Sciences versus Heavy Equipment or Oil and Gas, its usage may vary greatly. There may also be specific requirements or regulations within the industry that could help you eliminate options, especially given the rise of environmental concerns.

-

Application Type: The type of application it’s used in plays a big role in how a seal will perform over time. In a static application, where the seal doesn't move, long-term chemical exposure could break down the seal and affect performance. In a dynamic application, where the seal is moving around, it could wear out faster than expected.

-

Temperature: Temperature can have a big impact on how chemicals behave and how seals perform. Depending on the material, high temperatures can cause damage or failure, while colder temperatures can affect how well they seal.

-

Pressure: Pressure changes can directly impact seal performance by altering chemical interactions with its surroundings. Rubber seals, for example, can be damaged or change shape in high-pressure conditions. Other seals, like PTFE Teflon®, can allow gas permeation or other media flow in low-pressure conditions.

Common Seal Materials and Their Chemical Compatibility

Seals come in various materials, each with its unique chemical properties. Whether you're considering Nitrile for its versatility or Viton® for high-temperature applications, understanding each material's chemical profile is paramount.

Industry leader charts, such as the chemical compatibility chart from Parker, provide valuable information on which materials are resistant to specific media. This information is crucial in selecting the right seal material for the job.

How to Simplify Seal Selection Based on Chemical Compatibility

-

Identify the media. Begin by understanding the fluid or gas your seal will encounter. (Pro tip: imagine the Venn diagram).

-

Consider the operating conditions. Understand the environment, application type, temperature, and pressure ranges your seal will operate within.

-

Research material compatibility. Use resources like the Parker compatibility chart to match your needs with the right material.

-

Verify your selection: We always recommend testing your seal in real or simulated conditions to ensure it's the right fit.

Conclusion

The path to the perfect seal is a journey of understanding, research, and testing. With chemical compatibility as your compass, you can navigate the complexities with confidence. Remember, it's not just about finding a seal; it's about finding the right seal. And with this guide, you're one step closer.

If you need help navigating this process to find the right seal for your project, talk to a seal expert at Wyatt Seal. We’ve spent 50 years building relationships with seal manufacturers worldwide to offer you access to thousands of seals, gaskets, O-rings, and other specialty items for any application.

.webp?width=6720&height=4480&name=AdobeStock_436872741%20(compressed).webp)