When reliable sealing is critical, selecting the right elastomer makes all the difference. Two of the most capable materials on the market—FKM (fluoroelastomer) and FFKM (perfluoroelastomer)—are often compared for their impressive chemical and temperature resistance.reliability.

Wyatt Seal Blog

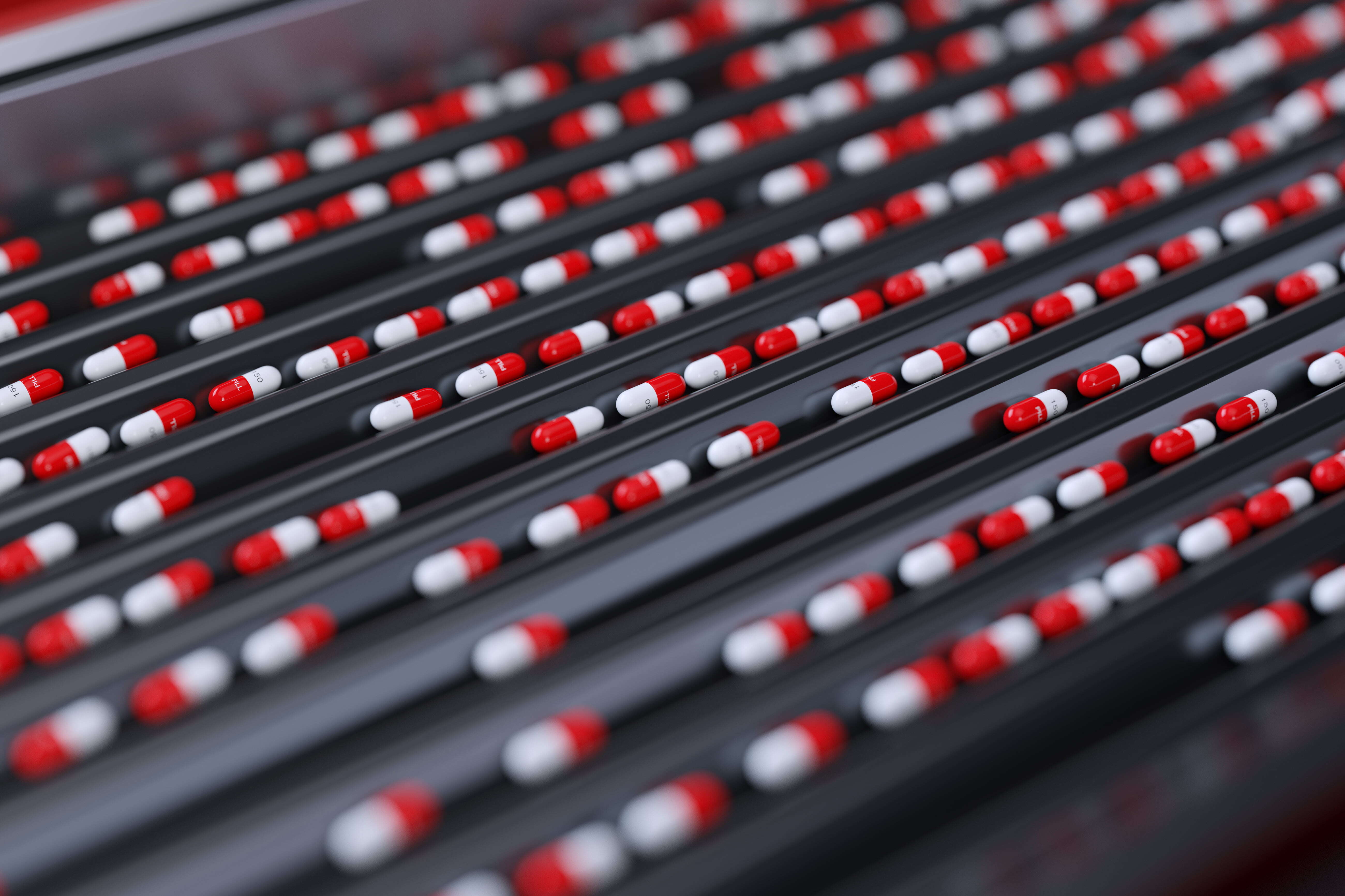

In pharmaceutical manufacturing, maintaining product integrity, preventing contamination, and ensuring compliance with regulations are top priorities.

Metal detectable O-rings are essential for maintaining safety in the food and beverage industry’s production processes. Combining rubber and metal fillers, these innovative seals ensure that any contamination caused by seal degradation is quickly identified using metal detectors or X-ray scanners.

When an O-ring is said to be “food grade,” it’s understood to meet a rigorous standard of quality and cleanliness.

Food and beverage manufacturers operate in some of the most highly regulated production environments in the world. From sanitation chemicals and temperature swings to strict FDA requirements, sealing components must perform flawlessly to protect product quality and keep lines running.

Central to the effectiveness of O-rings is the concept of "squeeze" – a measurement of the deformation they undergo when compressed against their mating hardware.